Hengyang Huayi Machinery Co., Ltd., a leading manufacturer of advanced rubber molding machinery, is proud to announce its official relocation to a new manufacturing facility. This pivotal move, completed in Aug of 2025, marks a significant milestone in the company’s journey, stands for a new era of technological innovation, expanded production capabilities, and optimized client service.

New plant area scope: 80000 Square Meters, Total investments: 150000000.00 CNY,Below are overview of the new facility.

In addition to upgrading our hardware to a smart modern manufacturer plant , we have carried out a full-scale renovation of our internal management system to enhance overall efficiency and precision.

ERP System – Integrated Production Management

Streamlining resources and workflow for seamless coordination and traceability.MES System – Visualized Production Process

Real-time monitoring ensures transparency, precision, and efficiency across every production stage.PLM System – Optimized Production Capacity

Enhancing product lifecycle management for faster innovation and reduced time-to-market.LEAN Production Management – Quality Improvement & Cost Reduction

Continuous optimization to ensure premium quality, minimal waste, and higher productivity.

Key Advantages of Hengyang Huayi Machinery Co., Ltd.

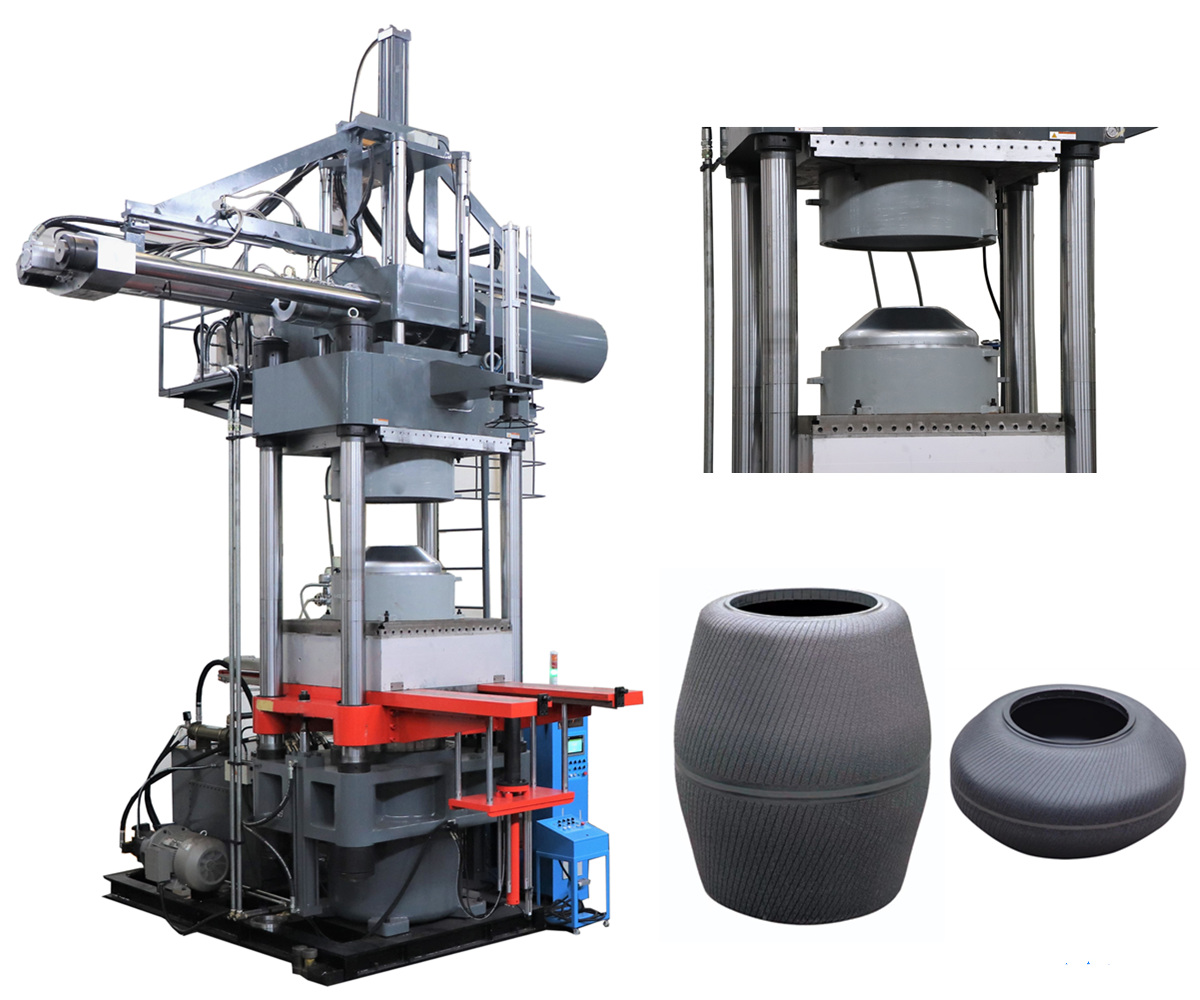

As a leading manufacturer of advanced rubber injection molding machines, Hengyang Huayi Machinery Co., Ltd. stands out through superior technology, precision engineering, and customer-centered innovation. Our machines deliver reliability, efficiency, and performance trusted by industries worldwide.

1. High Precision and Consistency

Huayi machines are designed for high-pressure, high-precision injection molding, ensuring exceptional mold accuracy, smooth product surfaces, and tight dimensional tolerances — meeting even the most demanding industrial standards.

2. High Efficiency and Productivity

Compared with traditional molding methods, Huayi machines can boost production efficiency by up to 30%. Advanced material flow systems and optimized cycle times deliver faster throughput and higher output with minimal waste.

3. Design Flexibility and Versatility

Our Liquid Silicone Rubber (LSR) and rubber injection molding machines support the manufacturing of complex shapes and multifunctional components — offering designers maximum flexibility and creativity in product development.

4. Stability and Durability

Built with robust structures such as the four-column vertical design, Huayi machines ensure long-term stability, durability, and reliable operation under continuous industrial conditions.

5. User-Friendly Operation

Featuring intuitive control interfaces and humanized operating systems, Huayi machines are easy to learn and operate. This design minimizes operator errors while maximizing efficiency and productivity on the production floor.

6. Modular Design and Customization

Our modular system architecture allows customers to easily customize machines for different product types and production scales — offering flexibility to adapt as manufacturing needs evolve.

7. Cost Reduction

With optimized material usage, reduced labor intensity, and improved production yield, Huayi machines help customers lower operational costs and increase overall profitability.

8. Reliable After-Sales Service and Support

Backed by decades of experience in the rubber machinery industry, Huayi provides comprehensive after-sales support, including on-site installation, operator training, and remote technical assistance — ensuring worry-free service and long-term success.

9. Wide Range of Applications

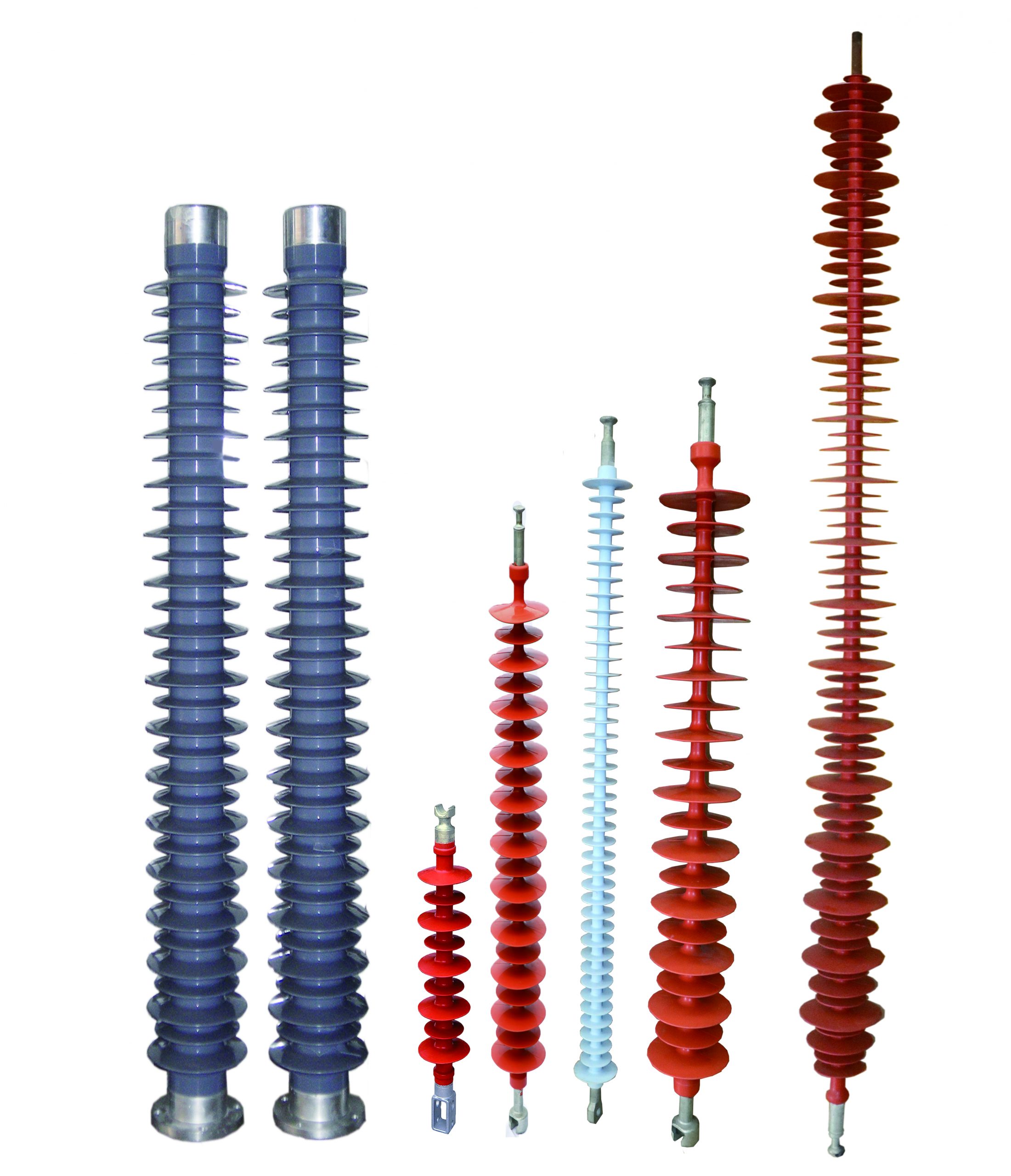

Huayi’s rubber injection molding machines are widely used across multiple industries, including automotive, railway infrastructure, electrical power transmission, and mechanical seals, helping global manufacturers achieve higher performance and reliability.

New Plant Address:No.16 Industry road, Baishazhou Industry Zone, Hengyang City, Hunan Province,China.Post Code:421007

Posted by Sharon.Yi

Email:machine@hwayimachine.com

Whatapp:+8613907344348