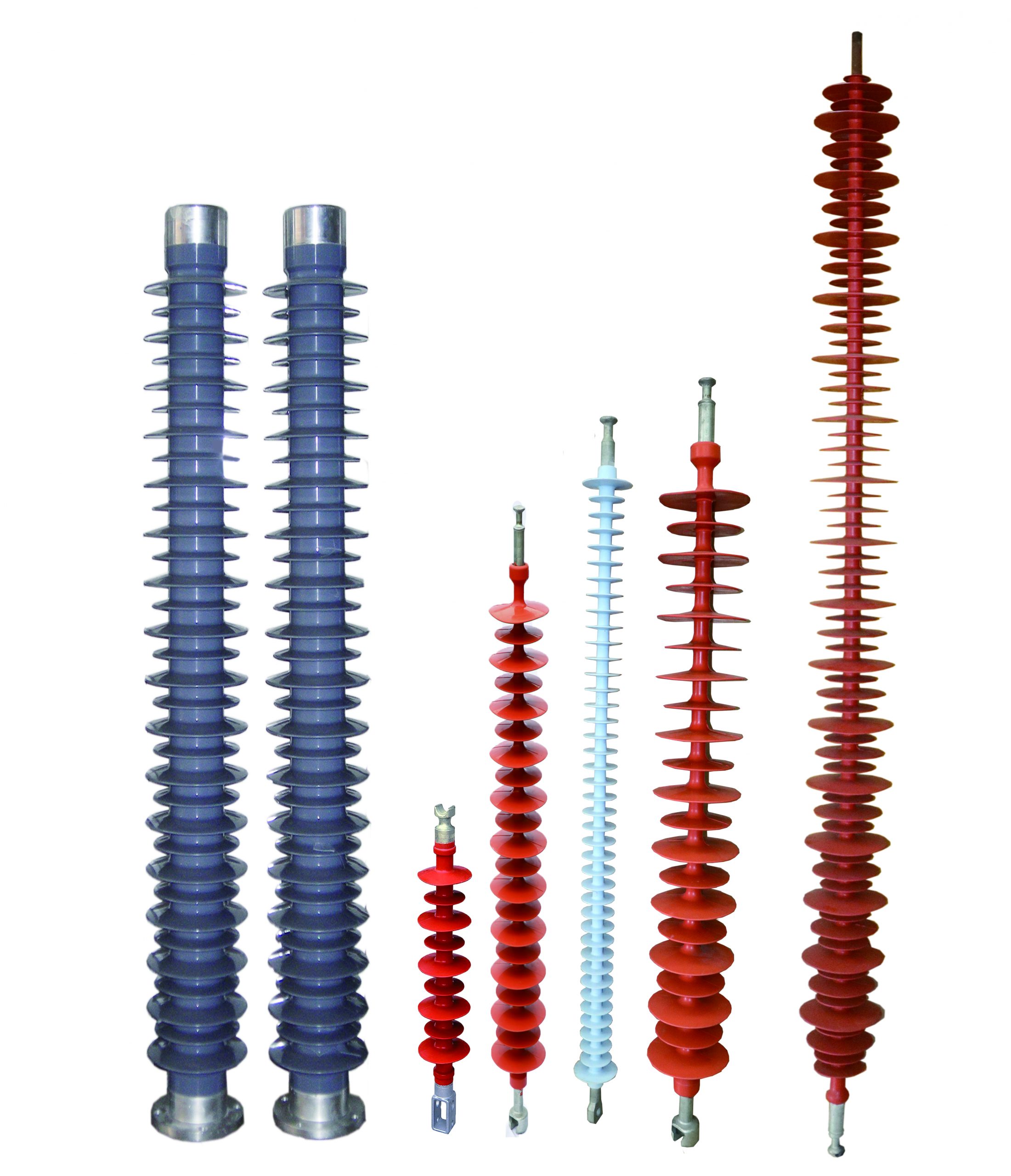

How to Make Composite Rubber Insulators: A Guide for Beginners

Many newcomers to the composite insulator industry often ask us: How are rubber insulators made? What type of equipment is used in the production process? With 25 years of experience in manufacturing rubber insulators, Huayi Machinery is here to guide you through the details.

35KV surge arrester atuo ejection(2)

Material Selection: Liquid Silicone or Solid Silicone?

- If you plan to use liquid silicone, we recommend our P series or F series machines equipped with an LSR pump system.

- For solid silicone, the B series rubber injection machine is the ideal choice.

- Unsure about which material to choose? Conduct a quick market survey in your region. If liquid silicone insulators are more common, opt for liquid silicone; if solid silicone is dominant, go for solid silicone.

- Still confused about the difference between liquid and solid silicone? Send us a qualified sample, and we will assist you in determining the best option.

Producing Different Sizes of Composite Insulators and Mold Sharing

To produce different sizes of composite insulators efficiently, consider the following approach:

- If the insulators share the same shed diameter, rod diameter, but differ only in creepage distance, you can save costs by using one mold base with interchangeable mold inserts. This allows you to create insulators of varying lengths without needing multiple molds, providing an economical solution.

Construction of Silicone Rubber Insulators

Silicone rubber insulators belong to the category of composite insulators and consist of three main components:

- An external layer made of silicone rubber

- A fiberglass-reinforced plastic (FRP) core rod

- Metal fittings

Compared to porcelain insulators, silicone rubber insulators are easier to manufacture and are more environmentally friendly. For sourcing FRP rods and metal fittings, there are numerous reliable suppliers available in China, which can be found through platforms like Alibaba, industry exhibitions, or recommended by us.

Essential Equipment for Manufacturing Insulators

Here’s a breakdown of the equipment needed for producing silicone rubber insulators:

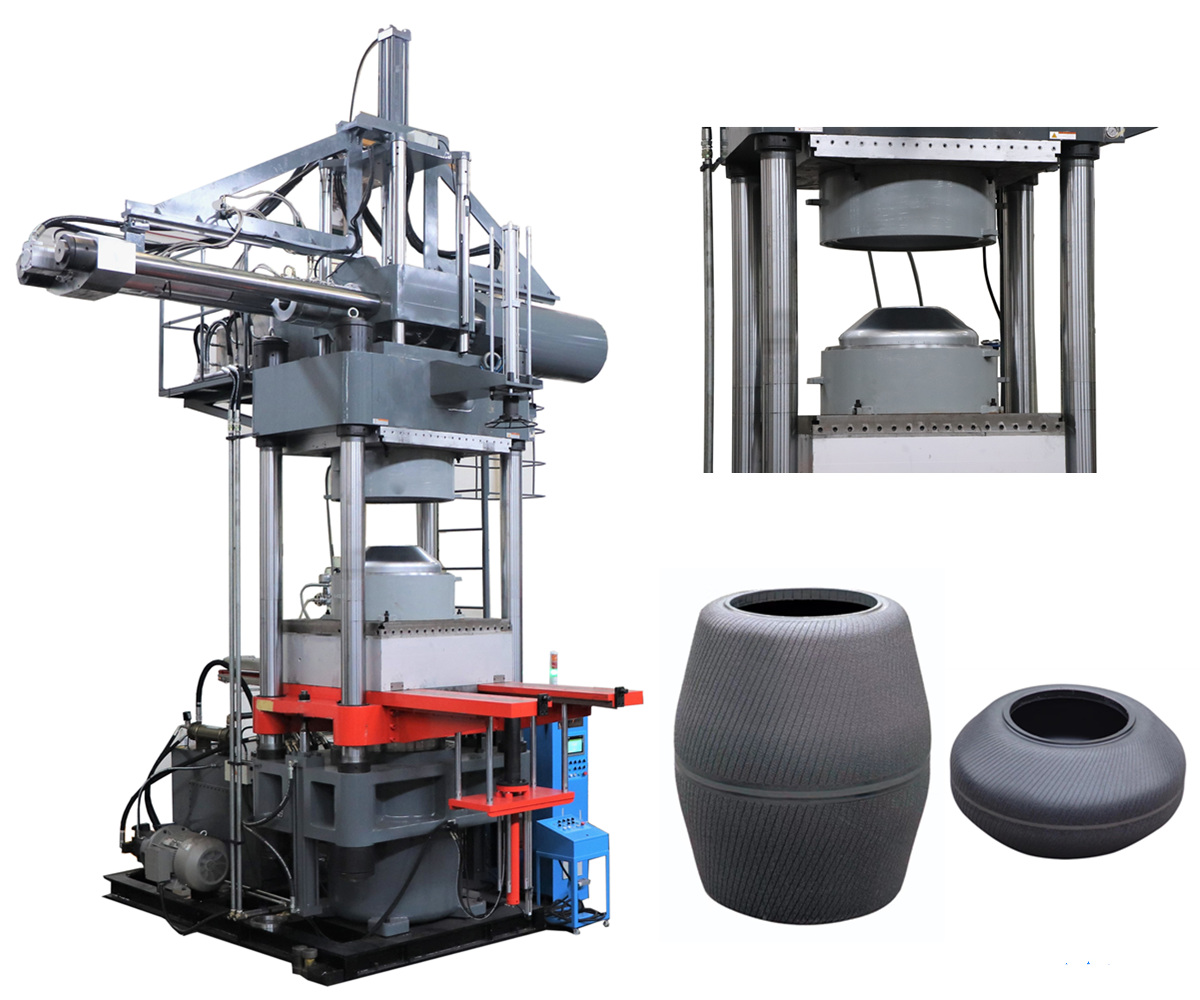

- Molding Equipment: Solid rubber molding machine or liquid rubber molding machine, depending on your material choice.

- Molds: Customized based on the insulator design.

- Water Chiller: To maintain optimal temperature during the molding process.

- Rod Pre-heating Device: Prepares the FRP rod for better adhesion with the silicone rubber.

- Optional Investments(if budget and technical expertise allow):

- Rubber mixing machine

- Lab testing devices for quality assurance

- Rod and fitting clamping machine for assembly

For beginners entering the industry, partnering with a professional insulator manufacturing company can provide valuable technical support and certification assistance. This ensures compliance with state grid requirements and helps you obtain necessary approvals.

By understanding these key aspects, newcomers can establish a clear road map for producing high-quality silicone rubber insulators while optimizing costs and efficiency.

Posted by Sharon.Yi

Tel:+8613907344348

Email:machine@hwayimachine.com

Production Link:

https://www.facebook.com/share/v/1BkcVZrwKf/