How to make rubber tire bladder?

When it comes to manufacturing rubber tire bladders, precision, efficiency, stability and energy saving are the key concerns.

Hengyang Huayi Rubber Machinery — a trusted leader in the industry — stands at the forefront of innovation, providing advanced equipment and turnkey solutions for high-quality rubber bladder production.

In this article, we’ll introduce how rubber tire bladders are made and our core advantages.

1. Material Preparation

Prepare the rubber compound — including natural rubber, additives, and other ingredients — and mix them thoroughly in the mixing mill.

After mixing, the compound is cut, weighed, and preheated for injection.

⚠️ Always check the shelf life of raw materials to ensure no aged or expired compound is used before molding.

2.Injection Process

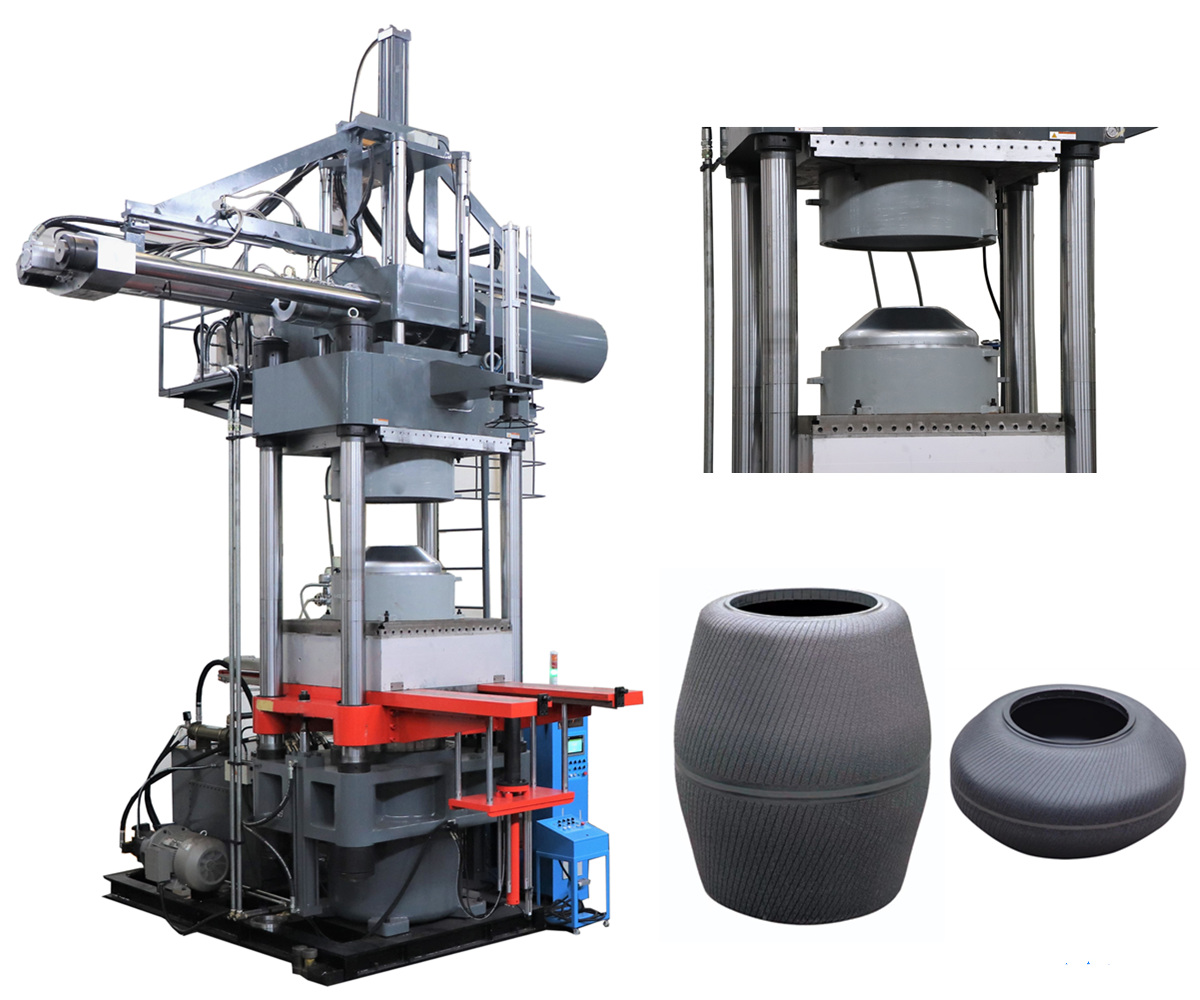

At this stage, Huayi’s high-precision rubber injection molding machines come into play. Using First-In-First-Out (FIFO) injection technology, the preheated rubber is injected into the bladder mold cavity at controlled pressure and temperature.

Servo-driven injection system ensures accuracy within ±0.5%.

SIEMENS or B&R PLC control provides intelligent and responsive operation.

Energy-saving servo system reduces power consumption by 30–70%.

Rexroth hydraulic valves ensure smooth, stable, and repeatable pressure control.

The mold is heated evenly, allowing the rubber to vulcanize under consistent temperature and pressure. Once cured, the bladder is de-molded, cooled, and inspected for quality.

3.Production Video

Below is the video shows the whole production process

https://www.facebook.com/share/v/19ueiZtQUv/

4. Machine Technical Parameters

Here is technical parameter of machine with different clamping force,

5.Hengyang Huayi Key advantage include:

25+ years of expertise in rubber injection molding technology.

Founder Mr. Du Xingwu, a Tsinghua University engineer who developed China’s first rubber injection molding machine and co-edited the Rubber Machinery Design Manual (6th Edition).

Complete solution support, from material mixing to injection molding and automation.

Global service network with engineers and representatives in India, Brazil, Argentina, and the USA.

Remote diagnostic systems for real-time technical assistance and troubleshooting.

If you have interest to know more details or need more help, please contact with sales representatives for help.

Posted by Sharon.Yi

Email:machine@hwayimachine.com

Telephone:+8613907344348